roughing end mill depth of cut

The depth of cut of solid end mills needs to be set appropriately according to the machining method workpiece material and cutting edge geometry. 12 DIAMETER OF CUT X 12 DIAMETER OF SHANK.

Guide How To Select The Best Cnc End Mill

They may seem similar to many people Skip to content 86-18505123093 86.

. Made of solid carbide these end mills are harder stronger and more wear resistant than high-speed steel and cobalt steel for the longest life and best finish on hard. I replaced end mill and rerun and see end mill goes in a drilled hole 125 deep and feeds to 2nd. Smooth cutting paths without rapid changes in direction or cutting parameters reduce the load on the end mill and improve end mill life significantly With a shallow depth of.

1 NEW MELIN TOOL COMPANY CRMG-1616-AITiN SOLID CARBIDE FINE PROFILING ROUGHING END MILLSIZE. Solid Carbide End Mill for Roughing of Steels Stainless Steel Cast Iron. Carbide Square End Mills.

Multi-Cut end mills are specifically designed for high-performance roughing operations. KenCut RR Solid Carbide End Mill for Roughing of Steels Stainless Steel Cast Iron. RF 100 Speed End Mills.

CLICK to browse 16 DEPTH OF CUT MM ROUGHING GENERAL PURPOSE END MILLS made by world class cutting tool manufacturer Guhring. Running program the other day and i notice broken 58 dia roughing HSS end mill. Normally i would use a depth of cut of31 to625 with a625 dia roughing end mill for a full width slot feeding straight across g1 The tooth design allows for little to no vibration.

For high-speed roughing width of cut is usually set at somewhere between 5 and 10 percent of the cutting tool diameter. Up to 16 cash back Reduce your cutting forces by reducing speed andor feed or axial andor radial depth of cut. Out of the most common milling tools there are roughing end mill and finish end mill.

1445 Commerce Avenue Brookfield WI 53045. Roughing End Mills also known as ripping cutters or hoggers are designed to remove large amounts of metal quickly and more efficiently than standard end mills. This means a 050-inch end mill will be engaged 0025.

Due to variable spacing of flutes combined with the NR roughing profile vibrations. Increase your systems rigidity by changing over to a stub length end mill or. The depth of cut is set at.

RF 100 90 End.

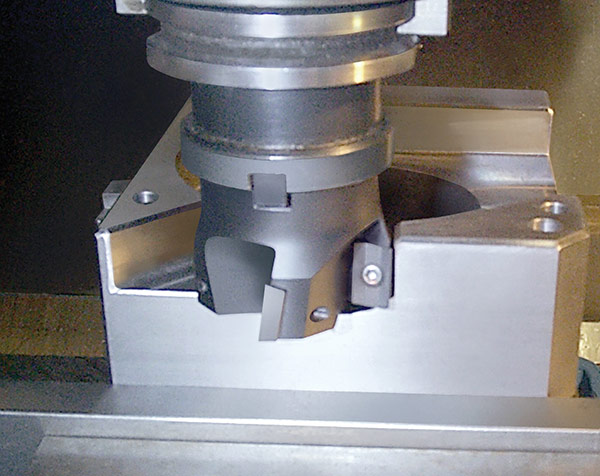

Shell End Milling Cutter Turbo 12 Seco Tools Insert Roughing Semi Finishing

End Mill An Overview Sciencedirect Topics

Article Roughing Choosing Between Square Shoulder Button Cutters Dapra Corporation

What Is Roughing Market Prospects

Milling Products Cutting Tools Metalworking Hanes Supply Inc

Roughing End Mill Ame Moldino The Edge To Innovation Moldino Tool Engineering Ltd

Solid Carbide Roughing End Mill 4 Flute Cnc Milling Cutter Bits Router Bit For 50 Hrc Metal Roughing Machining 6mm To 20mm Router Bits For Metal Cutter Bitrouter Bit Aliexpress

Iscar Cutting Tools Metal Working Tools Milling Plunging Recessing

3 Pack 9 16 Dia X 1 1 4 Loc X 3 1 2 Oal Roughing End Mills The End Mill Store

Face Milling Cutters And Finishing Cutters Avantec Zerspantechnik

High Efficiency Vs High Feed Milling Which Is More Productive Modern Machine Shop

Effects Of Cutting Conditions For Turning Mitsubishi Materials Corporation

Shell End Milling Cutter Turbo 18 Seco Tools Insert Roughing Semi Finishing

Iscar Cutting Tools Metal Working Tools Milling Plunging Recessing

Guide How To Select The Best Cnc End Mill

Cutting Conditions For Rough Cutting Download Table

Diving Into The Depth Of Cut In The Loupe Machinist Blog

Amazon Com Wokesi 8mm Cutting Diameter 2mm Cutting Depth 8mm Shank Diameter Hrc48 4flutes Solid Carbide T Slot End Mill Cnc Lathe Router Bits Keyseat Roughing Profiling Tools 8mmdia2mmdepth8mmshank Hrc48 Industrial Scientific